Progressive rate compression springs are relatively common, but Rockford Spring Company was recently challenged with a project that required matching a load profile very closely throughout the entire range of the spring.

The details of our customer's end product are proprietary, but we can share a general overview of the project. Our customer is building a very high precision piece of scientific equipment which requires accuracies in alignment of the magnetic components of less than 10 millionths of an inch. The spring required must counterbalance the magnetic forces precisely in order to maintain an accurate adjustment of the magnetic field.

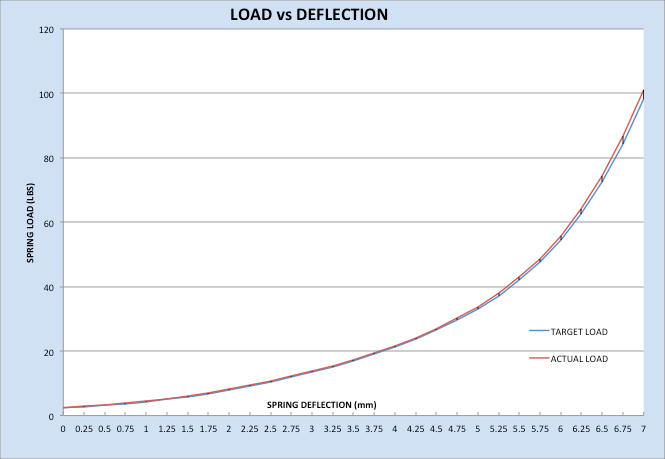

RSC was provided a load profile which represented the load created when the magnetic components were adjusted closer together. The load climbed from just a few pounds to over 100lbs in about .280" of travel. The profile of the magnetic load and the load generated by a spring from our latest shipment are plotted on the graph. A successful design required considerable calculations to determine the change in rate for every .020" of travel, the number of active coils and the diameter of each coil required to generate the exact rate and force profile. From these characteristics we were able to calculate the pitch and diameter required for each quarter turn of the spring. Once we had established the geometry of the spring, our set-up personnel was challenged with the task of producing a spring which varied precisely in pitch and diameter to produce the required load profile. This of course meant a lot of patience with adjustments and load measurements preformed dozens of times over several days to finally produce the exact geometry and achieve a matching load profile.

Our customer was very pleased with the results, "The Rockford conical springs significantly simplify the mechanical design of undulators making them attractive for future generations of accelerator-based x-ray sources."

These results were only possible because everyone in the process including Sales, Quoting, Engineering, Quality Control and Production is accustomed to attempting and achieving results that are often deemed impossible by other companies. Tackling the most difficult jobs has helped us learn the skills and patience needed to meet our customer's most difficult challenges and expectations.

Four springs are used in each alignment station. Two of our springs in the first station are circled.